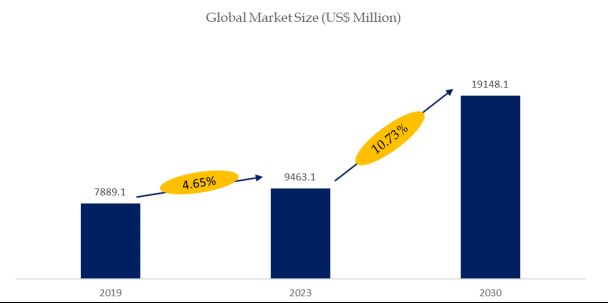

Five-Axis Linkage High-End CNC Machine Tool Research:CAGR of 10.73% during the forecast period

Five-Axis Linkage High-End CNC Machine Tool

Five-axis linkage high-end CNC machine tools are precision machining equipment with the capability of multi-axis linkage motion. They are mainly used for processing complex curved surface parts, such as aerospace parts, automotive engine parts, etc. The five-axis linkage high-end CNC machine tool includes three linear coordinate axes X, Y, and Z and two rotary coordinate axes A and C, which can realize high-precision processing of parts in multiple directions. Through the combined motion of different axes, complex curved surface parts can be effectively processed and processing accuracy and efficiency improved. Five-axis linkage CNC machine tools have high-speed, high-precision processing capabilities and are suitable for processing difficult and high-precision parts. They are widely used in aerospace, automobile manufacturing and other fields.

- Global Five-Axis Linkage High-End CNC Machine Tool MarketSize(US$ Million), 2019-2030

Above data is based on report from QYResearch: Global Five-Axis Linkage High-End CNC Machine Tool Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to the new market research report “Global Five-Axis Linkage High-End CNC Machine Tool Market Report 2024-2030”, published by QYResearch, the global Five-Axis Linkage High-End CNC Machine Tool market size is projected to reach USD 19.15 billion by 2030, at a CAGR of 10.73% during the forecast period.

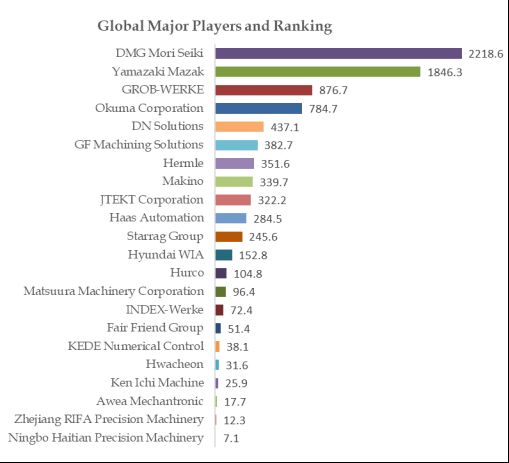

- Global Five-Axis Linkage High-End CNC Machine Tool Top22Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Above data is based on report from QYResearch: Global Five-Axis Linkage High-End CNC Machine Tool Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Five-Axis Linkage High-End CNC Machine Tool include DMG Mori Seiki, Yamazaki Mazak, GROB-WERKE, Okuma Corporation, DN Solutions, GF Machining Solutions, Hermle, Makino, JTEKT Corporation, Haas Automation, etc. In 2023, the global top five players had a share approximately 65.0% in terms of revenue, the global top 10 players had a share approximately 80.0% in terms of revenue.

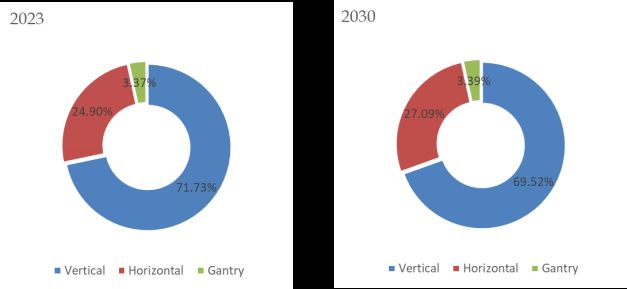

- Five-Axis Linkage High-End CNC Machine Tool,Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global Five-Axis Linkage High-End CNC Machine Tool Market Report 2024-2030.

In terms of product type, currently Vertical is the largest segment, hold a share of 71.73%.

In terms of product application, currently Aerospace is the largest segment, hold a share of 49.33%.

As far as product production is concerned, Asia-Pacific is currently the main production region, accounting for approximately 36.79%.

From the perspective of product consumption, Asia-Pacific is currently the largest consumer region, accounting for approximately 37.05% of the market share.

Market Drivers:

- Intelligent Upgrading of Manufacturing Industry: As the manufacturing industry transforms towards digitalization and intelligence, five-axis linkage high-end CNC machine tools are promoted to provide support for manufacturing automation and intelligent upgrading.

- Government Policy Support: Five-axis linkage high-end CNC machine tools, as high-precision processing equipments, are of great significance to the manufacturing industry. The support from relevant government policies has become an important driving factor for its development.

- Market Demand: Five-axis linkage high-end CNC machine tools are high-end equipments, and market demand continues to increase, driving their continuous development.

Restraint:

- Technical Research: Five-axis linkage high-end CNC machine tools are technically complex and require overcoming multiple core technologies.

- Higher Cost: The production cost of five-axis linkage high-end CNC machine tools is high and the price is relatively expensive, resulting in their relatively weak competitiveness in the market.

Trend:

- Intelligence and Automation: In the future, five-axis linkage high-end CNC machine tools will continue to develop in the direction of intelligence, high speed, and high precision. With the application of artificial intelligence, big data, cloud computing and other technologies, five-axis CNC machine tools will have stronger automation and intelligence capabilities, further improving processing efficiency and accuracy.

- Industrial Cluster Development: Five-axis linkage high-end CNC machine tools will develop in the direction of industrial clustering, build a complete industrial chain, and improve the competitiveness of the entire industry.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

English

Simon Lee

English

Hitesh

Chinese

Damon

Japanese

Tang Xin

Korean

Sung-Bin Yoon

Competition

Key players, new entrants,acquisitions, mergers and expansions,development trends and challenges.

Industry Analysis

Rawmaterial, application, product type, demand,supply,downstream, supply chain etc.

Market Size

Capacity, production, sales, revenue, price, cost etc.

Customized Information

We can offer customized survey and information to meet ourclient's need.