Wafer Surface Defect Detection Equipment Market Trends:the global market size is projected to reach USD 2.14 billion by 2030

Wafer surface defect detection equipment refers to advanced inspection tools and systems designed to identify and analyze imperfections or irregularities on the surface of semiconductor wafers. These defects can include scratches, pits, particles, and pattern deviations, which can adversely affect the performance and yield of semiconductor devices. The primary goal of this equipment is to ensure the quality and reliability of wafers used in the production of integrated circuits (ICs) and other semiconductor components.

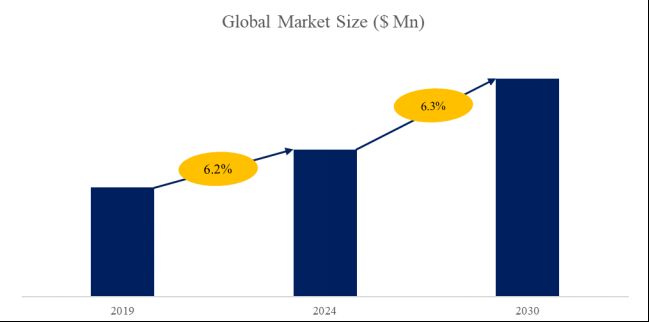

According to the new market research report “Wafer Surface Defect Detection Equipment- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030”, published by QYResearch, the global Wafer Surface Defect Detection Equipment market size is projected to reach USD 2.14 billion by 2030, at a CAGR of 6.3% during the forecast period.

- Global Wafer Surface Defect Detection Equipment MarketSize(US$ Million), 2019-2030

Source: QYResearch, "Wafer Surface Defect Detection Equipment- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030”

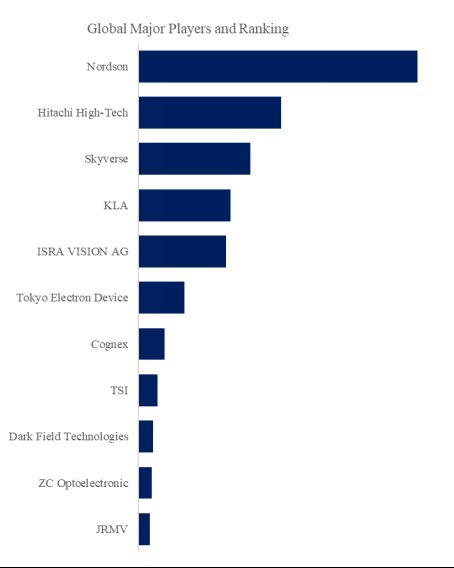

- Global Wafer Surface Defect Detection Equipment Top11Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Source: QYResearch, "Wafer Surface Defect Detection Equipment- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030”

According to QYResearch Top Players Research Center, the global key manufacturers of Wafer Surface Defect Detection Equipment include Nordson, Hitachi High-Tech, Skyverse, KLA, ISRA VISION AG, Tokyo Electron Device, Cognex, TSI, Dark Field Technologies, ZC Optoelectronic, etc. In 2023, the global top five players had a share approximately 59.0% in terms of revenue.

Market Drivers:

The growing use of semiconductor devices in various applications such as consumer electronics, automotive, telecommunications, and industrial sectors drives the need for high-quality wafers, boosting the demand for defect detection equipment.

As semiconductor technology advances, including the development of smaller nodes and more complex architectures, the need for precise defect detection becomes more critical, driving the market for advanced detection equipment.

Restraint:

The high cost of advanced wafer surface defect detection equipment can be a significant barrier, particularly for small and medium-sized enterprises.

The complexity of operating and maintaining defect detection equipment requires skilled personnel, which can be a limitation for some manufacturers.

Trends:

The integration of artificial intelligence (AI) and machine learning algorithms in defect detection systems is a growing trend. These technologies enhance the accuracy and speed of defect identification and classification.

Increasing automation in semiconductor manufacturing processes, including defect detection, is driving the development of automated inspection systems that can operate with minimal human intervention.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

Contact Us:

If you have any queries regarding this report or if you would like further information, please contact us:

QY Research Inc.

Add: 17890 Castleton Street Suite 369 City of Industry CA 91748 United States

E-mail: global@qyresearch.com

Tel: 001-626-842-1666(US) 0086-133 1872 9947(CN)

EN: https://www.qyresearch.com

JP: https://www.qyresearch.co.jp

English

Simon Lee

English

Hitesh

Chinese

Damon

Japanese

Tang Xin

Korean

Sung-Bin Yoon

Competition

Key players, new entrants,acquisitions, mergers and expansions,development trends and challenges.

Industry Analysis

Rawmaterial, application, product type, demand,supply,downstream, supply chain etc.

Market Size

Capacity, production, sales, revenue, price, cost etc.

Customized Information

We can offer customized survey and information to meet ourclient's need.