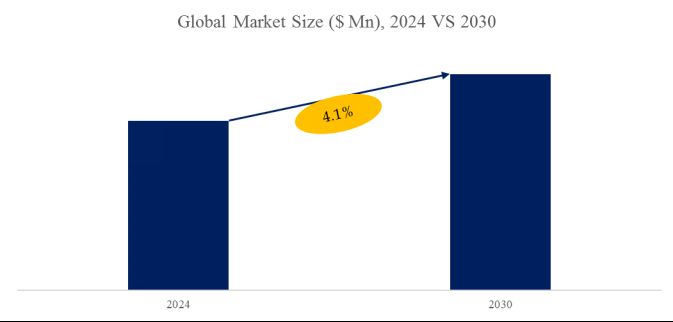

Hot Runner Market Report: the global Hot Runner market size is projected to reach USD 4.4 billion by 2030

According to the new market research report Hot Runner- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030”, published by QYResearch, the global Hot Runner market size is projected to reach USD 4.4 billion by 2030, at a CAGR of 4.1% during the forecast period.

- Global Hot Runner MarketSize(US$ Million), 2019-2030

Source: QYResearch, "Hot Runner- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030”

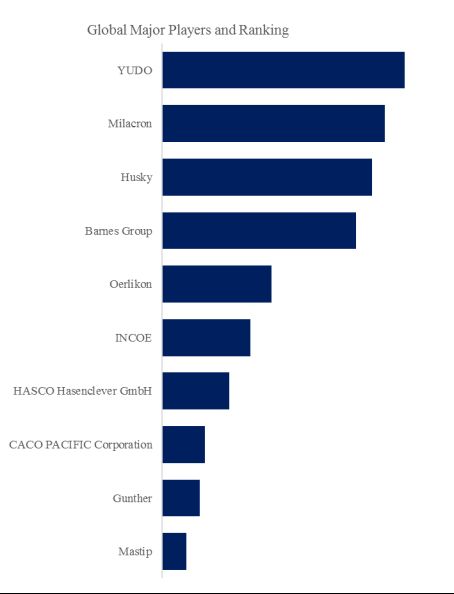

- Global Hot Runner Top10Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Source: QYResearch, "Hot Runner- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030”

According to QYResearch Top Players Research Center, the global key manufacturers of Hot Runner include YUDO, Milacron, Husky, Barnes Group, Oerlikon, INCOE, HASCO Hasenclever GmbH, CACO PACIFIC Corporation, Gunther, Mastip, etc. In 2023, the global top 10 players had a share approximately 70.0% in terms of revenue.

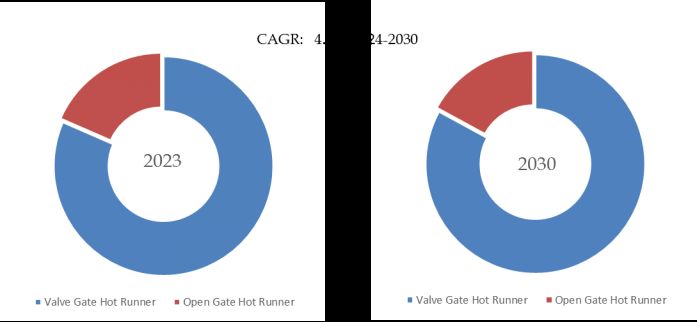

- Hot Runner,Global Market Size, Split by Product Segment

Source: QYResearch, "Hot Runner- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030”

In terms of product type, currently Valve Gate Hot Runner is the largest segment, hold a share of 81.7%.

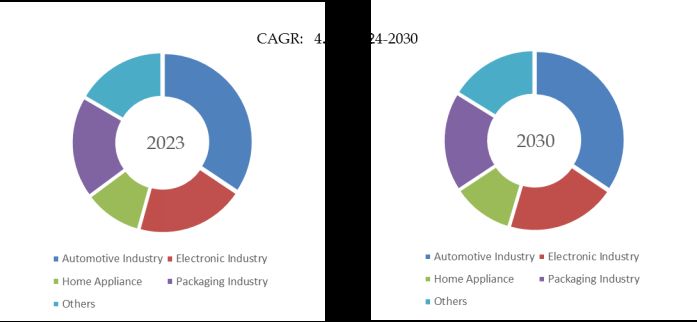

- Hot Runner,Global Market Size, Split by ApplicationSegment

Source: QYResearch, "Hot Runner- Global Market Share and Ranking, Overall Sales and Demand Forecast 2024-2030”

In terms of product application, currently Automotive Industry is the largest segment, hold a share of 34.5%.

Market Drivers:

Many countries are implementing stricter regulations to minimize plastic waste, pushing the injection molding industry to become more efficient. Traditional methods, such as cold runners or sub-runners, generate significant waste, which is now less acceptable. The industry is shifting towards hot runner systems to comply with these regulations, as they significantly reduce plastic waste by eliminating the need for excess runners, thus supporting sustainable manufacturing practices.

The increasing costs of resin are driving customers to invest in runner-less, hot runner technology. As resin prices climb, manufacturers seek ways to optimize material usage and reduce waste. Hot runner systems provide a solution by minimizing material consumption during the injection molding process. This not only helps in controlling costs but also enhances the overall efficiency of production, making it a financially viable option for many companies.

Hot runner technology offers significant advantages in terms of cycle times and production output for injection molding machines. By enabling faster cycle times, hot runners increase the speed of production, allowing manufacturers to meet higher demands more effectively. Additionally, the improved efficiency reduces downtime and operational costs, making hot runner systems a crucial investment for companies looking to enhance productivity and profitability in their manufacturing processes.

Restraint:

The main raw materials for hot runner systems, such as PTFE and die steel, experience frequent price fluctuations. These materials are highly sensitive to changes in the economic environment, including crude oil and iron ore prices. Such volatility poses significant challenges for manufacturers, as it affects production costs and profit margins. Companies must continuously adapt their procurement strategies and pricing models to manage these fluctuations effectively.

The hot runner industry is highly fragmented, leading to intense competition among numerous players. This competitive landscape makes it difficult for individual companies to gain significant market share and maintain profitability. Firms must differentiate themselves through innovation, quality, and customer service to stay ahead. Additionally, competitive pressures can drive down prices, further squeezing profit margins and necessitating continuous improvements in efficiency and cost management.

Opportunity:

3D printing is revolutionizing the production of cooling bushes for tip-heating (thermal closure nozzles) technology. This innovative approach allows for more precise and efficient manufacturing processes. Customization and rapid prototyping capabilities provided by 3D printing enhance performance and reduce production costs, driving the advancement of thermal management solutions in hot runner systems.

High oil prices are making biopolymers and biodegradable plastics more competitive. These resins, derived from biomass, offer an environmentally friendly alternative to traditional plastics. The increased use of these materials is driven by growing environmental awareness and regulatory pressures, encouraging manufacturers to adopt sustainable practices and reduce their carbon footprint.

Sandwich molding technology is gaining traction for its ability to incorporate recycled materials into new products. By covering recycled plastics with layers of new resin, manufacturers can produce high-quality packaging for food and beverages. This method not only promotes recycling but also meets the stringent safety and quality standards required in the packaging industry.

The electric vehicle (EV) market is experiencing rapid growth, leading to increased demand for connectors and battery-related plastic parts. As the automotive industry shifts towards electrification, hot runner molds play a crucial role in producing these components efficiently. The trend is expected to continue, driven by advancements in EV technology and rising consumer demand for sustainable transportation options. Also, there is a shift from simpler commodity polymers to more complex engineering grades, driven by trends such as light weighting in automotive.

About The Authors

|

Lu Jing - Lead Author |

|

Email: lujing@qyresearch.com |

|

Lu Jing is a technology & market senior analyst specializing in chemical, advanced material, and component. Lu has 9 years’ experience in chemical and focuses on catalyst and additive, metal and plastic materials, waste recycling, daily chemicals. She is engaged in the development of technology and market reports and is also involved in custom projects. |

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 17 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

English

Simon Lee

English

Hitesh

Chinese

Damon

Japanese

Tang Xin

Korean

Sung-Bin Yoon

Competition

Key players, new entrants,acquisitions, mergers and expansions,development trends and challenges.

Industry Analysis

Rawmaterial, application, product type, demand,supply,downstream, supply chain etc.

Market Size

Capacity, production, sales, revenue, price, cost etc.

Customized Information

We can offer customized survey and information to meet ourclient's need.